Powering Efficiency and Versatility of an Air Compressor

Table of Contents

Introduction

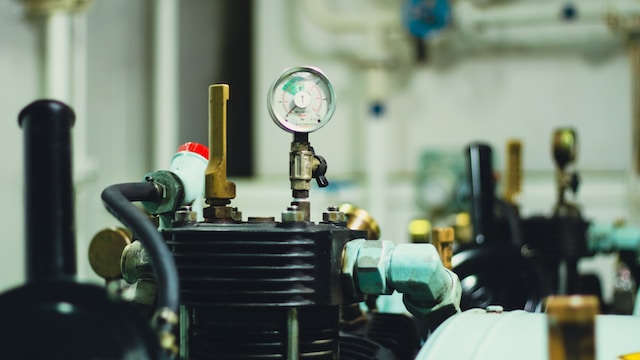

An air compressor is a versatile tool vital in various industries and applications. It utilizes compressed air to pneumatic power tools, inflates tires, operates machinery, and more. In this article, we will explore the world of air compressors, their functions, benefits, and the different types available in the market.

Understanding Air Compressors

An air compressor is a mechanical device that transforms the potential energy contained in compressed air into power from an electric motor. This compressed air is a significant resource in many settings since it may be used for a variety of functions.

The Functions of an Air Compressor

Air compressors are used in numerous applications across industries. Some of the common functions include:

- Powering Pneumatic Tools: Air compressors provide the necessary power to operate pneumatic tools such as nail guns, impact wrenches, paint sprayers, and sanders. They offer a consistent and efficient power source for these tools, increasing productivity and ease of use.

- Air compressors come be handy for swiftly inflating sports balls, bicycle tyres, automobile tyres, and other inflatable equipment. They speed up and simplify the process when the appropriate attachments are used.

- Operating Machinery and Equipment: Many industrial machines use air compressors to power their operations. Air compressors drive processes such as material handling and machine automation from manufacturing plants to construction sites.

- Cleaning and Blowing: Air compressors are used for cleaning and blowing duties such blowing away debris, dusting surfaces, and drying equipment. They deliver a stream of air at high pressure that efficiently cleans debris and dirt from a variety of surfaces.

Benefits of Air Compressors

Investing in an air compressor brings several benefits to both residential and commercial users:

- Efficiency and Versatility: For a variety of jobs, air compressors provide a dependable and effective power source. They offer consistent performance and adaptability by handling a variety of tools and applications.

- Cost Savings: Using an air compressor eliminates the need for individual power sources for each pneumatic tool. This reduces energy costs and lets for more efficient use of resources.

- Increased Productivity: Productivity is increased because air-powered equipment are frequently quicker and more powerful than their electric counterparts.

- Compact and Portable: Many air compressors are designed to be compact and portable, allowing for easy transportation and use in various locations.

Types of Air Compressors

Air compressors come in different types, each suitable for specific applications:

- Reciprocating (Piston) Compressors: These compressors use pistons and cylinder arrangements to compress air. They are available in single-stage and two-stage configurations, with varying levels of power and capacity.

- Rotary Screw Compressors: These compressors compress air using two interlocking screws. They are noted for operating continuously, which qualifies them for applications with high demand.

- Centrifugal compressors: These compressors are frequently employed in expansive industrial applications. They are renowned for their excellent efficiency and capacity and compress air using centrifugal force.

- Scroll Compressors: These compressors compress air using a scrolling mechanism. They are suitable for small-scale and domestic applications since they are frequently more compact and quiet than other types.

Choosing the Right Air Compressor

Several aspects should be taken into account while choosing an air compressor, including:

- Required Air Pressure and Volume: Determine your intended applications’ specific pressure and volume requirements to ensure the compressor can meet those needs.

- Power Source: Consider whether you need an electric-powered or gasoline-powered compressor based on your availability of power sources and portability requirements.

- Tank Size and Capacity: Evaluate the tank size and capacity to ensure it aligns with the demands of your applications. A larger tank will provide a longer continuous operation without frequent refilling.

- Noise Level: If noise is a concern, opt for compressors designed to operate fas tly, especially in residential or noise-sensitive environments.

Also Read: 5 Types of Airport Advertising You Should Be Aware Of

Conclusion

Air compressors are necessary equipment that promote effectiveness, adaptability, and higher productivity in a range of fields and applications. Whether you need to run machinery, fill tyres, or power pneumatic tools, selecting the best air compressor will guarantee optimum performance. When choosing an air compressor for your needs, take into account your unique requirements, desired features, and the various models that are available.